• At Busworld 2019 Solaris presents three zero-emission vehicles • Solaris Urbino 18 electric – zero-emission bus with new batteries • Solaris Urbino 12 hydrogen – new generation hydrogen vehicle • Solaris Trollino 24 – a bi-articulated platform for zero emission public transportation vehicles • Solaris talks. Forum on modern public transportation. A series of presentations held every day, at 1.00 p.m. at the company's stand

Solaris has been developing its portfolio of alternative drivelines vehicles for over ten years now, having become one of the top players on the European electromobility market. Thanks to the tenders won by Solaris in the past weeks, the firm has turned a European leader in terms of deals secured for electric buses. The electric buses supplied by the company to 16 countries so far have traversed over 20 million kilometres in total, in varying climate conditions.

At this year’s edition of Busworld exhibition in Brussels on 18-23 October, Solaris is presenting three new vehicles. All of them are fitted with zero-emission at the point of operation drivelines.

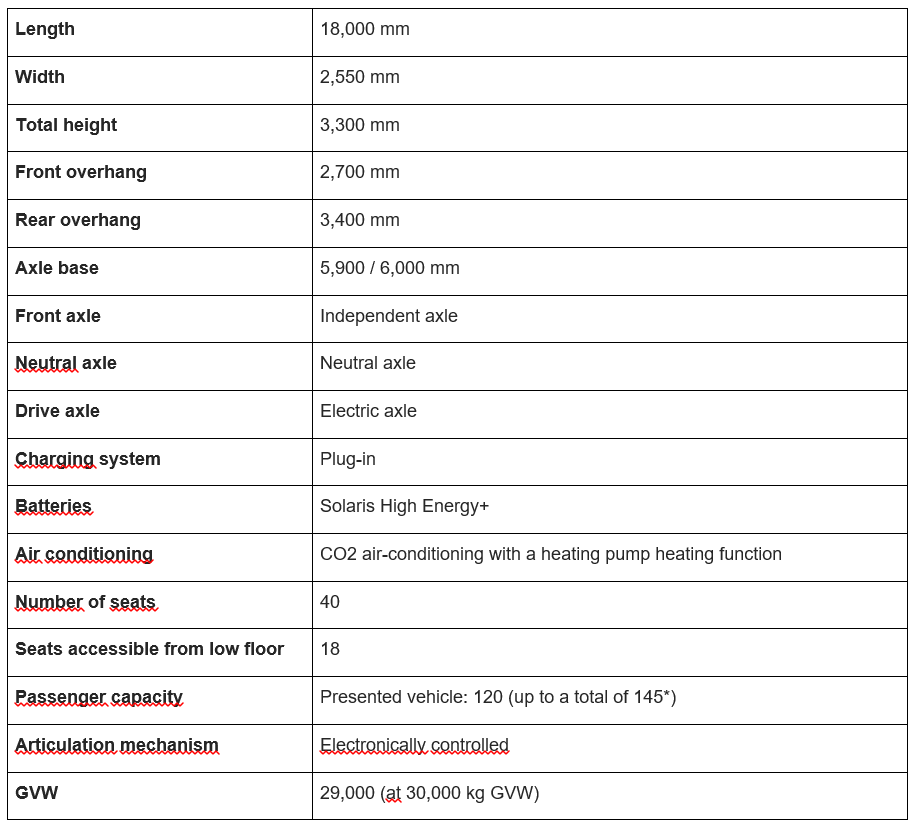

Solaris Urbino 18 electric

Nowadays, the distinctive line of the articulated Urbino 18 electric is known to many operators; over 200 models have been commissioned by clients so far. The bus displayed at the Busworld, however, has been uniquely equipped.

What is an absolute novelty is the new-generation Solaris High Energy+ batteries which the manufacturer is showing in Brussels for the first time. The batteries stand out on account of their high energy density, thanks to which the bus will easily be able to cover 200 km on a single charging session, irrespective of road and weather conditions. However, the perfected parameters of the energy storage will also allow to maintain a still significant passenger load at a much increased range – there will be room for 120 people on board of the articulated electric bus, 40 of them seated. 7 battery packs with a total capacity of 553 kWh have been installed in the Urbino 18 electric. 3 batteries have been stowed away in the rear end of the vehicle, and four – on the roof of the first section. The bus is charged via a plug-in connector or pantograph charging - depends on operator’s preferences.

The Solaris Urbino 18 electric on display has also been equipped with advanced driver assistance systems (ADAS) which significantly increase both travel comfort and – above all – safety. The Mobileye Shield+ device remedies the risk of collisions with pedestrians or cyclists thanks to a system of smart cameras which constantly monitor the so-called blind spots in a vehicle. The driver is alerted to potential dangers with audio and visual signals.

What is more, the electric Solaris will feature the system initiating automatic braking, i.e. the CMS (Collision Mitigation System). When a radar installed on top of the bus detects the risk of a potential head-on collision, the system goes into braking mode, reducing velocity and thus alleviating the consequences of a potential collision.

Where the side mirrors would be conventionally, the 18-meter Solaris features cameras that ensure improved visibility not only in bright sunlight, but also during rain or snowfall, as well as at night. What is more, the cameras increase the field of view substantially and they improve the aerodynamics of the vehicle. This new solution is already available for the whole Urbino family.

In order to reduce the energy consumption as much as possible, the articulated Urbino electric features air conditioning with a heat pump which uses heat from the outside to generate an adequate temperature inside the vehicle. This device uses carbon dioxide as the working medium which is currently considered the most environment-friendly solution. The implementation of the CO2 heat pump is intended to enhance the energy efficacy of the vehicle, and thus increase its drive range, but also to reduce noxiousness.

Yet another innovation applied in the vehicle is a traction inverter produced in the originative SiC technology, i.e. using silicon carbide. Owing to this, the device can operate at higher voltage, frequencies and temperatures, which in turn, results in a significant reduction of the mass and size of the power converter and in a general increase in efficiency of the whole system.

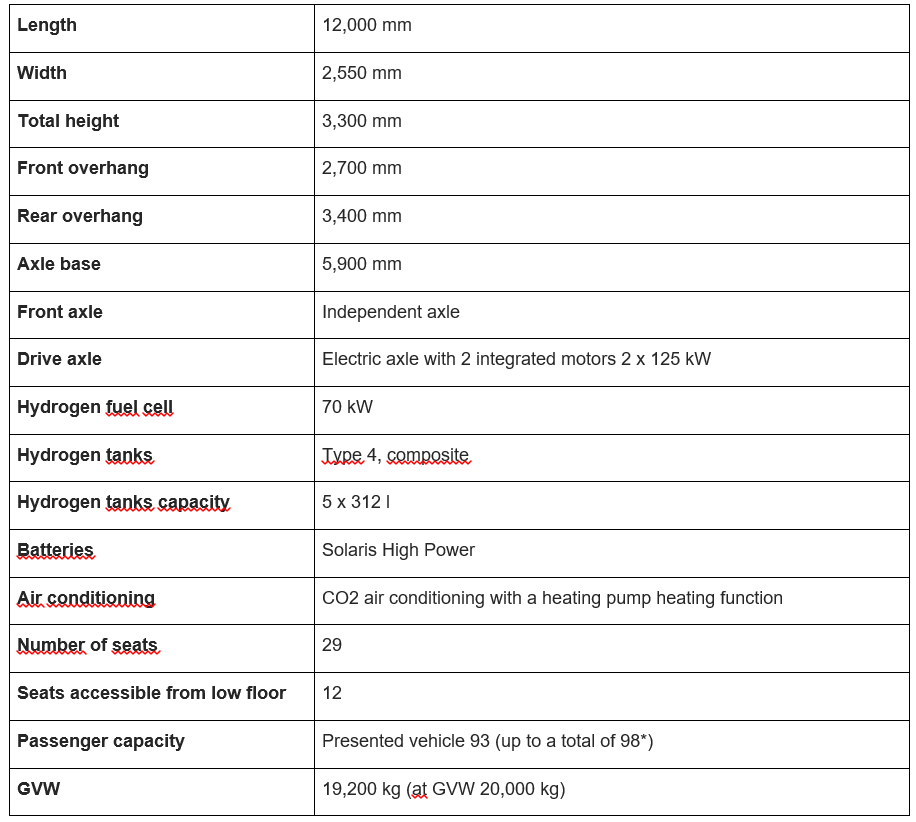

Solaris Urbino 12 hydrogen

Solaris was one of the first electric bus manufacturers to direct its research and development efforts towards electric drivelines. Nearly a decade after the première of its first e-bus, Solaris is now supplementing its zero-emission bus range with the Urbino 12 hydrogen in which hydrogen is transformed into electric energy, which is then directly fed into the driveline of the vehicle. Hydrogen technology used for power generation will enable buses to traverse even longer distances completely emission-free.

Hydrogen-fuelled buses will allow to create a complementary emission-free bus portfolio thanks to which Solaris will be braced for contemporary challenges and the diverse needs of customers with regard to range, flexibility and operability of vehicles. The manufacturer believes that the development of all electromobility branches, be that battery buses, trolleybuses or hydrogen-fuelled vehicles, should proceed in synergy, and that this process is indispensable to ensure sustainable transport of the future. Therefore, hydrogen-powered buses of Solaris will not constitute competition for battery buses or models of the Trollino series. Quite the opposite: these technologies will complement each other perfectly and they will all benefit from the technological progress of electric drivelines and their components.

The advantages of hydrogen as an energy source are indisputable. Thanks to its density and lightness, this element may constitute a clean energy source for vehicles, and it may enable them to cover a distance of up to several hundred kilometres. Considering the fact that hydrogen can be produced from water in the electrolysis process, it constitutes a really clean source of energy. It is also a perfect solution for operators who have access to hydrogen derived from renewable sources, or from the industrial processes. Using reverse electrolysis, hydrogen fuel cells are relatively small in size and they generate energy during the operation of the vehicle. That is why they are an ideal solution when a long drive range has to be ensured. Hydrogen refilling takes little time and is quite convenient, not differing much in essence from refilling a vehicle with other fuels (e.g. CNG).

Solaris gained its first experience in hydrogen when it designed battery vehicles using fuel cells as range extenders. As part of the JIVE initiative, Solaris has supplied two Urbino 18.75 electric to Hamburg and 10 trolleybuses with hydrogen-based range extenders to Riga. At Busworld 2019, Solaris is taking its next steps towards progress presenting new generation of hydrogen bus – Solaris Urbino 12 hydrogen.

The Urbino 12 hydrogen is fitted with a cutting-edge fuel cell that acts as a miniature hydrogen power plant on board of the vehicle. Thanks to the use of advanced technology, the bus will be capable of covering up to 350 km on a single refill. In a hydrogen fuel cell, electric power is generated in a process called reverse electrolysis and then passed on directly to the driveline. The sole products of the chemical reaction occurring in the fuel cell are heat and steam. Consequently, the vehicle does not generate any noxious substances whatsoever.

A set of 70 kW fuel cells was used in the Solaris hydrogen buses. The hydrogen system also contains auxiliary devices, responsible for instance for the supply of hydrogen and oxygen at an adequate pressure, for the recirculation of the resource that has not been used up, and also for maintaining a proper and stable temperature of the fuel cells during operation.

The novelty of Solaris’ portfolio will be also fitted with a small Solaris High Power traction battery which is to support the fuel cell whenever the demand for energy is the highest. The battery is filled with energy derived from hydrogen and through the regenerative braking, though it is also possible to recharge it by means of a plug-in socket. Complementing the driveline is an axle with integrated electric motors.

As for the hydrogen storing technology, the Urbino 12 hydrogen features cutting-edge solutions. The chemical element is compressed in gaseous form at a pressure of 350 atmospheres into 5 new-generation tanks placed alongside the bus’ roof. Thanks to the use of type-4 hydrogen tanks, engineers of the Solaris Technical Office managed to reduce the mass of the cyllinders by ca. 20% compared to the parameters of the previous model. The set of composite tanks, placed longitudinally above the first axle of the vehicle, allows for a hydrogen storage capacity of 36.8 kg. A multifunctional valve is installed at the end of each tank; this valve includes a range of safety elements: a solenoid valve, an emergency valve activated by high temperature and an overload valve cutting off the flow of hydrogen in case of loss of containment of the system.

The exceptionally ecological Solaris Urbino 12 hydrogen is the result of consistent investments of the producer in zero-emission transport means. The hydrogen bus with a hydrogen fuel cell offers all the benefits of an electric driveline, such as reduced noise emission and vibrations, but it ensures above all a complete lack of emission of noxious substances at the site of operation. Vehicles featuring hydrogen technology also stand out thanks to their wide driving range and the short time needed to refill.

The vehicle displayed at Busworld 2019 has already found its first recipients. SASA Bolzano will be the first customer to receive the newest development of Solaris. Operator from north Italy, has ordered 12 units of the Urbino 12 hydrogen. The contract includes an 8-year service contract as well as a special training for drivers and service staff on the aspects of safe use and servicing of hydrogen vehicles. The deliveries are scheduled for 2021.

Moreover, the representatives of Solaris and Régie Autonome des Transports Parisiens (RATP) have signed a contract for lease and tests of the Urbino 12 hydrogen. The operator responsible for public transport in Paris will test the Solaris hydrogen bus in regular passenger traffic for a period of 10 weeks (April-June 2020). This is another step made by RATP in the preparations for transforming its fleet to completely zero emissions vehicles.

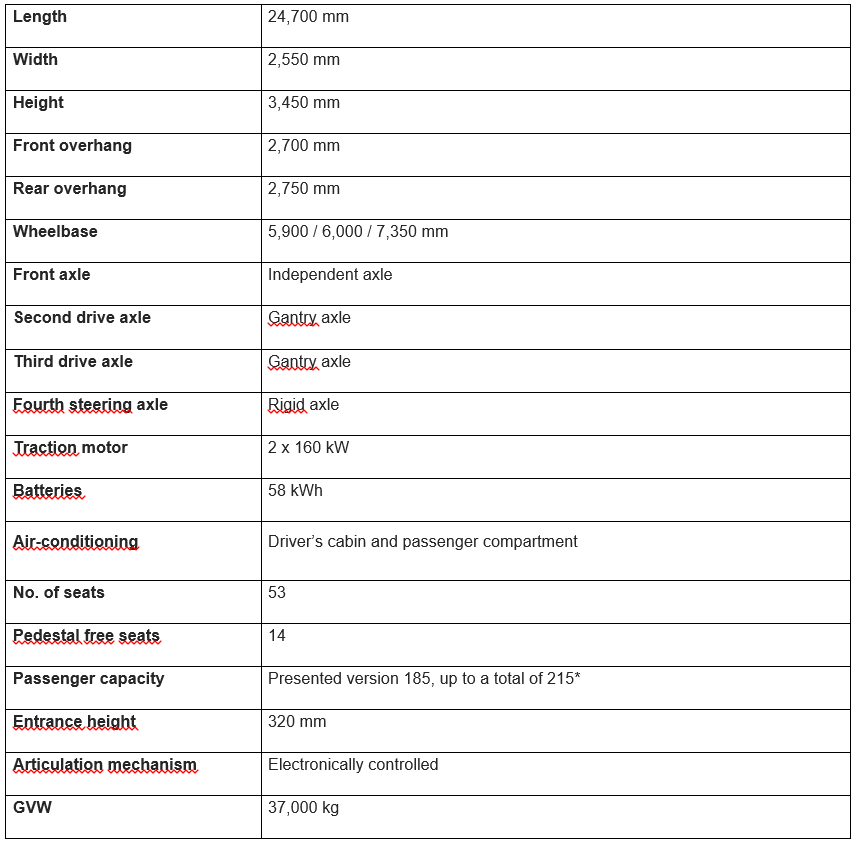

Solaris Trollino 24

Presented to the public for the first time at the Busworld 2019, the bi-articulated Trollino 24 is the longest vehicle assembled by the Polish manufacturer so far. The idea behind the Trollino was to create a platform for the future serial production of 24-metre vehicles with an electric or hybrid driveline and of trolleybuses. The Trollino 24 is a technically highly advanced model. Its driveline consists of two traction motors of 160 kW each, propelling two drive axles. A pack of 58 kWh batteries installed in the bus is charged during the drive, collecting current from the overhead line via a bipolar pantograph traditionally in use in trolleybuses. What is more, the energy accumulated in the batteries will be used to fuel the trolleybus whenever it is detached from the electric traction line. In order to ease manoeuvres in urban traffic, the fourth axle of the vehicle has also been made the steering axle. Apart from featuring a unique door layout of 1-2-2-2-2, the vehicle has also been fitted with an electric power steering (EPS) system, among others. Up to 215 persons will be able to ride on the trolleybus. This début model features cameras in lieu of side mirrors.

The Solaris Trollino 24 presented at this year's Busworld 2019 has been prepared in accordance with the MetroStyle design package. The unique design was developed for the exceptional bi-articulated vehicle. The decision on whether to offer the MetroStyle design version in other Solaris models will be made by the manufacturer at a later date.

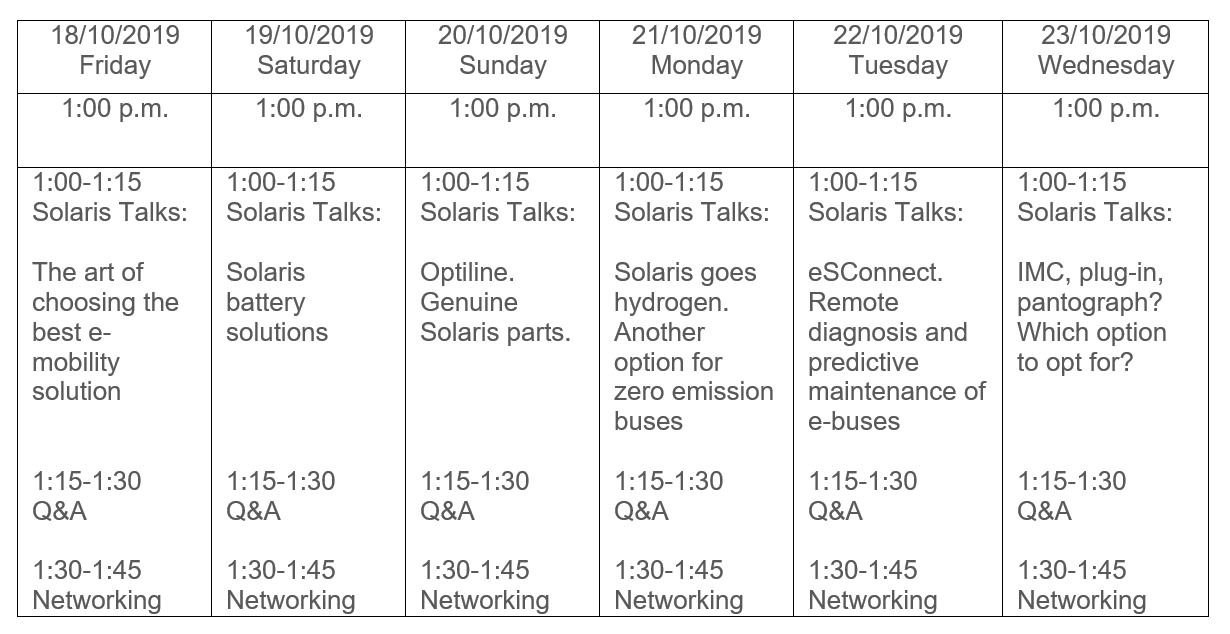

#SolarisTalks

Every day at the Solaris stand the manufacturer holds the #SolarisTalks forum to share its experience and information about its products. The forum is also an invitation to talk about modern technologies used in the area of e-mobility and the changing image of public transport. The topics of short presentations opening the discussion concern, among others types and selection of batteries, charging systems for buses and trolleybuses, hydrogen vehicles or remote diagnosis for electric buses.

More details on Solaris Talks

https://www.solarisbus.com/en/busworld2019

The new generation batteries – Solaris High Energy+

ADAS systems in Solaris buses.

- Solaris launching new generation Solaris High Energy+ batteries at Busworld 2019

- At least 200 km on a single charge, regardless of the weather conditions

- New ADAS (Advanced Driver Assistance Systems) solutions in Solaris vehicles increasing comfort and safety

Solaris batteries range for electric buses on offer

Back in 2011, when Solaris unveiled its first electric bus, its offer included only one battery option. Over the next years the company has remarkably extended its technical competence in this area. Over 20 million kilometres covered by the Urbino electric buses and experience gathered from the operation of vehicles in dozens of cities in various climates make it possible for Solaris today to offer the optimal battery solutions to its customers. Today, Solaris offers the following batteries to its electric buses: Solaris High Power, Solaris High Energy and Solaris High Energy+.

Solaris High Power

Solaris High Power batteries are characterised by a high “power density”. In practice, this means that the batteries can be recharged with high current, and consequently we can recharge them very quickly. These batteries come in packs with a nominal capacity of 29 kWh each. We can install up to 7 packs in one bus, which sums up to a maximum total capacity of over 200 kWh. Crucially, the batteries have a long life and a significant number of charging cycles. The firm is able to ensure an unlimited number of cycles over a period of 7 years.

Generally, the Solaris High Power battery can be charged using electricity equivalent to four times the capacity (4C). Thus, assuming that the bus features a battery of that type with a capacity of 116 kWh, then the maximum charging power for that battery will be 450 kW. Of course, engineers prefer to express the same parameter in ampere, because we do not use the same power throughout the whole battery charging process. So in fact we ought to say that the maximum current battery charging amperage amounts to 800 A. So far, Solaris has provided fast-charging pantograph stations for batteries of the High Power type with varying charging powers, reaching up to 560 kW!

The Solaris High Power batteries are used in circumstances when the frequent discharge and also recharge of batteries, usually using pantograph chargers, is assumed. Of course, power can be replenished also using plug-in charging stations. This is a perfect solution for those transport systems where fast pantograph charging stations, deployed along the vehicle route or at line terminals, are used to recharge electric buses. This type of battery has been installed by Solaris in electric buses operating in Brussels, Warsaw or Barcelona, for instance. It is worth noting that High Power batteries are also applied in the Trollino trolleybuses.

Solaris High Energy

The second type of batteries on offer are the Solaris High Energy. These have a relatively high capacity and are usually used in circumstances where a smaller number of “refills” during the day is assumed. The maximum charging power of that battery in kW corresponds to its energy capacity expressed in kWh. The nominal capacity of packs in that battery totals 50 kWh. The maximum, standard number of Solaris High Energy packs amounts to six for a 12-metre bus and to seven for an 18-metre vehicle. When applying this type of battery, we have the possibility to reach a nominal capacity of 350 kWh.

This is a solid solution for those operators who prefer a smaller number of recharging sessions throughout the day. Most often though, the energy in this type of battery is replenished at night, using chargers located at bus depots, i.e. when the buses are not running.

New development – Solaris High Energy+

The firm’s latest development are the Solaris High Energy+ batteries. These were designed by the Solaris Research and Development Department, bearing in mind the needs of carriers who want to cover at least 200 km on a single charge, regardless of the weather conditions, and thus regardless of air-conditioning or heating working.

The Solaris High Energy+ batteries are characterised by an extremely high energy density. Thanks to this feature, we manage to fit 79 kWh into one pack! This means that in the case of 7 packs – that is how many can be installed in an articulated bus at the most – we reach a nominal energy rate of 553 kWh! And 5 packs of that battery will fit into a 12-metre bus. This battery type can be recharged using a power equalling its capacity.

It may be worth underscoring that the solution is the result of cooperation between the Solaris and BZM Poland Research and Development Departments. Batteries of this type can be used only in Solaris vehicles and as of today, no other producer in the electric bus market is offering them.

The contractor executing the design initiated by Solaris is BMZ Poland, a leading European manufacturer of intelligent power supply and energy storage systems based on lithium-ion technology.

All of the above batteries, which are offered with electric buses of Solaris, boast a nominal voltage ranging between 600 and 700 V. The energy storage tanks used in the Urbino electric are capable of working in temperatures between -15 and +50 degrees Celsius. In order to optimise their efficiency, and to extend their service life, they are warmed up or cooled down. The battery cooling system is based on liquid-cooling.

New ADAS Solutions (Advanced Driver Assistance Systems) available in Solaris vehicles

Active driver assistance systems help drivers by performing certain actions before them or in their stead, and thus provide them with invaluable seconds for a proper response.

Solaris has presented at Busworld 2019 a vehicle with a new Collision Mitigation System (CMS) which initiates automatic braking. When a radar installed on top of the bus detects the risk of a potential head-on collision, the system goes into braking mode, reducing velocity and thus alleviating the consequences of a potential collision. The solution is already used in coaches and has now been applied in city buses. The correct calibration and configuration is of great significance in city buses where - contrary to coaches - there are no safety belts and most passengers ride standing rather than seated. Therefore the braking force is crucial for the passenger safety – and it is an additional challenge the manufacturers are facing.

Moreover, Solaris has presented new solution reducing “blind spot” effect for drivers. Cameras placed outside the vehicle detect pedestrians and cyclists who are not reflected in mirrors, especially during turns, even if it may seem to them that they must be visible to the driver. In order to solve this challenge, Solaris has availed itself of the Mobileye Shield+, a system warning the driver – with acoustic signals and visual alerts on the display – also in cases when changing lanes without adequate signalling beforehand or when no appropriate distance to the vehicle in front is maintained. The system also alerts the driver to collision risks. The device detects every pedestrian and cyclist within 80 cm from the bus, alerting the driver to their presence – again, acoustically and visually on a display. What the driver does not see in the mirror is pointed out to them by the camera steering device. Thus there is only one thing disappearing now, and that is doubts about the visibility on the road.

An enhanced visibility is also ensured by the completely re-designed mirrors, or rather cameras which project the image onto screens inside the vehicle. The ingenious design of the MirrorEye installed in lieu of regular rear-view mirrors corresponds to class 2 and 4 visibility (optionally class 5 in the right “mirror”) and this yields a whole range of advantages. Above all, there is no more need to reset and regulate mirrors after a driver switch – the screens and cameras always display the optimal scope regardless of the driver’s height. The width of the vehicle is reduced – which is of great importance on narrower and tight urban streets, and which also considerably reduces the risk of collision or of snagging the mirror on infrastructure items. What is more, the cameras substantially widen the field of view and they improve the aerodynamics of the vehicle.

The lack of mirrors enhances the safety of passengers, pedestrians and those waiting at the bus stop. The device employed up until now protruded from the bus contours, which involved the risk of hitting a person standing too close to a bus passing or turning into a bus pullout. The warmed cameras do not freeze nor fog up and, owing to their reduced size, are easier to clean or wash during the daily cleanup of a bus. What is more, the screens can also show distance thresholds of the various bus parts, such as its rear, particular doors or the axle. A horizontal line displayed on the screen eases manoeuvres and parking, and above all renders these procedures safer.

Technical specification - Solaris Urbino 18 electric

* max. passenger capacity for Solaris Urbino 18 electric

Technical specification - Solaris Urbino 12 hydrogen

* max. passenger capacity of Solaris Urbino 12 hydrogen

Technical specification - Solaris Trollino 24

* max. passenger capacity for Solaris Trollino 24 vehicle

* max. passenger capacity for Solaris Trollino 24 vehicle

Information Solaris

Additional information

Mateusz Figaszewski

Institutional Partnerships and External Relations Director

mateusz.figaszewski@solarisbus.com